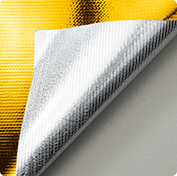

Nomex® Reinforced Aluminized Kapton® Film

Since 1985 Dunmore Aerospace has been providing material solutions for the space industry. Dunmore’s Nomex® reinforced aluminized Kapton® film product consists of an aluminized Kapton® film with a Nomex® scrim adhered over the aluminum coated surface. Nomex® scrim is selected for its heat resistance and superior strength properties. The material provides moderate absorptance and emissivity values and is an excellent choice for higher temperature applications.

Reasons to Choose Nomex® Reinforced Aluminized Kapton® Film

Nomex® reinforced aluminized polyimide film is useful in applications where the natural strength or tear resistance properties of aluminized Kapton® film are not sufficient for mission requirements. The addition of the Nomex® scrim strengthens the polyimide film from tearing that can be caused by handling or articulating components. The most common locations for Nomex® reinforced aluminized Dupont™ Kapton® film would be on the external layer of a multi-layer insulation (MLI) blanket since that surface is often handled during integration. Reinforced MLI films should also be considered when MLI blankets are attached to articulating components where the potential of ripping is high.

Nomex® reinforced aluminized Kapton® film would be selected over fiberglass reinforced MLI film products when wider temperature limits are required.

Material Properties

- Outside surface α / ϵ value: 0.63

- Operating Temperature: -200°C to 204°C

- Thickness: 139.7 μm

- Weight: 83 g/m2

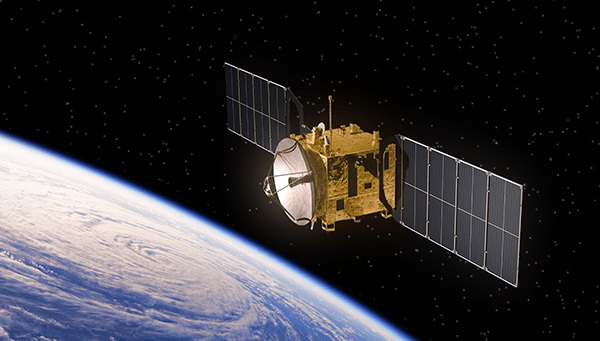

Nomex® Reinforced Aluminized Polyimide Film Application

Satellite MLI

DuPont™, Kapton® & Nomex® are registered trademarks of Dupont or its affiliates.