Radiant Barrier Film / Reflective Insulation Film

Dunmore is a leading manufacturer of low emittance films, which are used for radiant barrier and reflective insulation applications. Dunmore's products are a critical component to reduce the effects of radiant energy. The engineered radiant barrier films reflect up to 95% of radiant energy.

The various radiant barrier film products typically have the following critical values:

- Emissivity ≤ 0.05

Radiant Barrier Film for Humid Environments

In addition to the insulation properties of Dunmore’s radiant barrier insulation films, some applications expose the films to humid environments. The reflective insulation films are engineered with a proprietary anti-corrosion coating, which protects the highly reflective surface. Preventing the corrosion of the metal surface is critical to maintain the insulation properties. There is nominal degradation of the absorptance and emittance values over the life of the product.

Radiant Barrier Film Applications

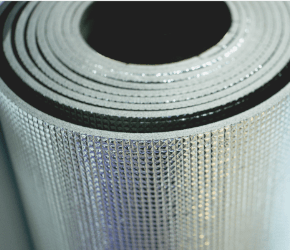

Bubble Insulation

Reflective Foam Insulation

Cold Chain Packaging

Radiant Barrier Insulation Film for Bubble Insulation

Dunmore’s radiant barrier PET film is widely used in the production of reflective bubble insulation. Since radiant barrier polyester film is not inherently compatible with the polyethylene bubble extrusion process, Dunmore offers a reflective insulation film product that has an polyethylene based adhesive layer. This ensures strong adhesion during and after the LDPE bubble extrusion process.

Typical Reflective Insulation Products

The main types of low emittance, radiant barrier insulation film Dunmore manufacturers are:

- Radiant barrier PET film (polyester)

- Radiant barrier BOPP film (biaxially oriented polypropylene)

- Radiant barrier PE film (polyethylene)