Fiberglass Reinforced Aluminized Kapton® Film

Since 1985 Dunmore Aerospace has been providing material solutions for the space industry. Dunmore’s fiberglass reinforced aluminized Kapton® film is a laminated film product that consists of aluminized Kapton® film bonded to woven glass fiber. The result is a lightweight tear and puncture resistant material with moderate absorptance and emissivity properties. The material is commonly used as the outer layer of an MLI blanket.

Reasons to Choose Fiberglass Reinforced Aluminized Polyimide Film

Fiberglass reinforced aluminized polyimide film is useful in MLI blanket applications where the natural strength or tear resistance properties of aluminized Kapton® film are not sufficient for your mission requirements. The addition of fiberglass strengthens the aluminized polyimide film for use in situations like technician handling or articulating components where there is a risk of puncture or tearing.

While Nomex® reinforced aluminized polyimide film also has ripstop properties, the main advantage of our fiberglass reinforced aluminized film is the weight of the material. If you are looking for a lightweight tear resistant option, our fiberglass reinforced product is the ideal solution. If your mission experiences more extreme temperatures, our Nomex® reinforced aluminized Kapton® film is a better choice since it has an operating temperature of -200°C to 204°C.

Fiberglass reinforced aluminized polyimide film is an excellent choice for:

- Applications that require tear and puncture resistance

- Moderately low to high temperature environments

- Moderate absorptance and emissivity applications

Material Properties

- Outside surface α / ϵ value: 0.72

- Operating Temperature: -140°C to 120°C

- Thickness: 61 μm

- Weight: 49.3 g/m2

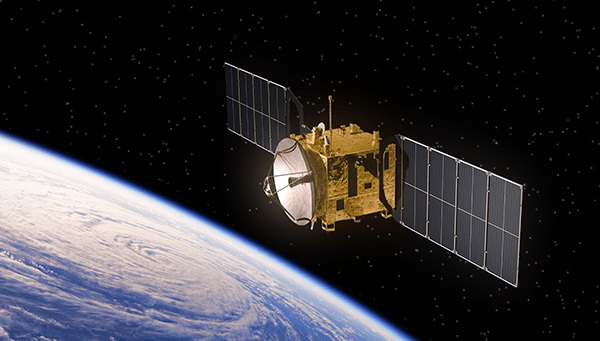

Fiberglass Reinforced Aluminized Kapton® Film Application

Satellite MLI

DuPont™, Kapton® & Nomex® are registered trademarks of Dupont or its affiliates.