Aluminized Kapton® Film

Dunmore is a leading manufacturer of aluminized Kapton® film, a widely used spacecraft material. There are many technical challenges associated with developing a spacecraft. The harsh space environment requires technical materials that function as a passive thermal management system.

Depending on the mission, a spacecraft can experience moderate to high heat conditions. Aluminized polyimide film reflects the thermal radiation exposure away from the spacecraft. This ensures a stable operating temperature for your critical hardware. Aluminized DuPont™ Kapton® film also protects the spacecraft from other space effects.

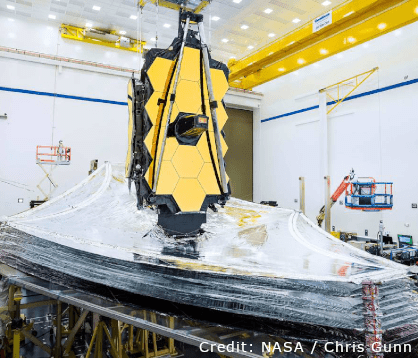

Using Aluminized Kapton® Film in an MLI Blanket

Metallized Kapton® films are critical materials used to fabricate multilayer insulation blankets. MLI blankets typically consist of 15 - 40 layers of films and fabrics. Each film layer can serve a different functional purpose in the overall MLI blanket design.

Aluminized polyimide film is commonly used in the following ways in an MLI blanket design:

- Cover layer

- Inner reflector layer

- Inner cover layer

The material protects the spacecraft by reflecting thermal radiation. This results in minimal heat transfer to and from the spacecraft. Metallized polyimide film is also the preferred material for the inner cover layer of an MLI blanket. Unlike polyester based materials, aluminized polyimide film has excellent flame retardant properties.

Reasons to Choose Aluminized Polyimide Film

- Minimize the heat flow transfer to and from a spacecraft

- Can withstand the extreme temperatures of space

- Superior radiation resistance with minimal physical changes

- Proven spaceflight heritage

Material Properties

- Typical outside surface α / ϵ value: 3.5

- Typical inside surface α / ϵ value: 0.63

- Operating temperature: -250°C to 290°C

- Thickness Range: 7.6 μm - 127 μm

- Product Types: Single Sided Aluminized Kapton® Film / Double Sided Aluminized Kapton® Film (DAK)

Aluminized Polyimide Film Applications

Satellite MLI

Sunshield

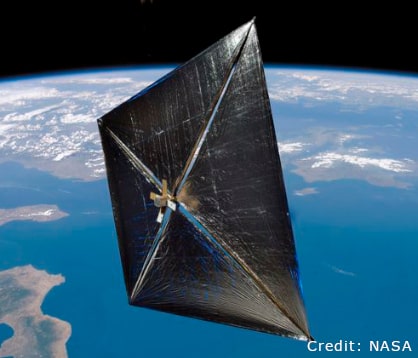

Solar Sail

DuPont™ and Kapton® are trademarks or registered trademarks of E.I. du Pont de Nemours and Company.