SiO2 Protected Aluminized Kapton® Film

Since 1985 Dunmore Aerospace has been providing material solutions for the space industry. SiO2 coated aluminized Kapton® film is constructed of an SiO2 coating on the first surface and an aluminum coating on the inside surface of polyimide film. The thermal management material is used as the outer surface (space facing side) of an MLI blanket for low to high temperature applications. SiO2 aluminized polyimide film has moderate absorptance and emissivity values along with protection against atomic oxygen (AO).

Reasons to Choose SiO2 Protected Aluminized Kapton® Film

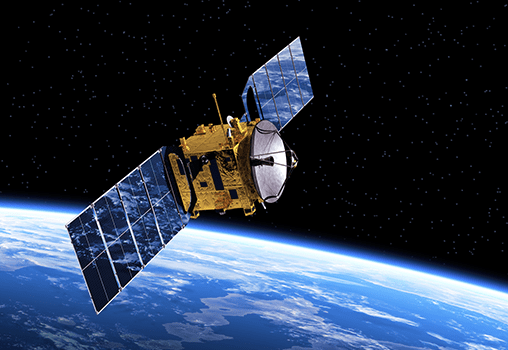

SiO2 coated aluminized Kapton® film is typically chosen to be used as the outer layer of MLI blankets on spacecraft that experience low solar heat fluxes like shaded surfaces, highly elliptical Earth orbits with long eclipses, and deep space missions. The silicon dioxide surface is resistant to atomic oxygen degradation that is mostly seen around Earth and other planetary bodies. In general, the optical properties and sink temperatures achieved by SiO2 aluminized polyimide film are comparable to bare aluminized Kapton® film.

SiO2 coated aluminized Kapton® film is excellent for:

- LEO missions that are exposed to atomic oxygen

- Low to high temperature environments

- Moderate absorptance and emissivity applications

Material Properties

- Typical outside surface α / ϵ values: 0.60 to 0.63

- Operating temperature: -251°C to 287°C

- Thickness Range: 25 μm - 127 μm

SiO2 Aluminized Polyimide Film Application

Satellite MLI

DuPont™ and Kapton® are trademarks or registered trademarks of E.I. du Pont de Nemours and Company.

Contact Us for SiO2 Aluminized Polyimide Film

Please Contact Us for more information on SiO2 Coated Aluminized Dupont™ Kapton® Film.