Kapton® Aramid Fabric Laminate

Since 1985 Dunmore Aerospace has been providing materials solutions for the space industry. Our Kapton® aramid fabric laminate is a tri-laminate structure consisting of aluminized Kapton® film laminated to Kevlar® fabric on one side and raw Kapton® film laminated to the other side of the aramid fabric. The material provides MMOD protection and low solar absorptance and emittance values for your MLI blanket design.

Reasons to Choose the Kapton® Aramid Fabric Laminate

Our Kapton® film fabric laminate is suitable for use as a stopper layer or space facing side of an MLI blanket for MMOD applications. Stopper layers work in conjunction with a disrupter layer (often aluminized beta cloth or Nextel® fabric) which absorbs the initial impact and breaks apart particles. The fragments that pass through the disrupter are slowed and stopped by the stopper layer, protecting the spacecraft underneath. The tri-laminate utilizes a heavier type of Kevlar® fabric, which provides superior impact resistance than the typical MMOD material. The low solar absorptance and emittance of the aluminized Kapton® film side additionally offers radiative thermal insulation.

Kapton® aramid fabric laminate is an excellent choice for:

- MMOD protection

- Superior impact resistance

- Applications requiring low solar absorptance and emittance

Material Properties

- Outside surface α / ϵ value: 3.5

- Operating temperature: -200°C to 204°C

- Thickness: 325.1 μm

Kapton Fabric Laminate Applications

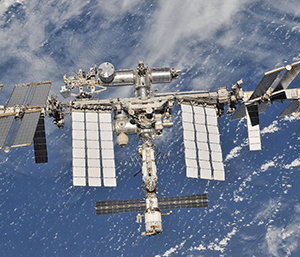

Space Stations, Credit: NASA

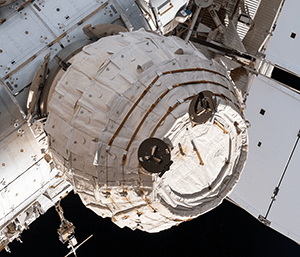

Inflatable Space Habitats, Credit: NASA

Satelllite MLI, Credit: NASA

DuPont™,Kapton®, Kevlar®, and Nomex® are trademarks or registered trademarks of E.I. du Pont de Nemours and Company.