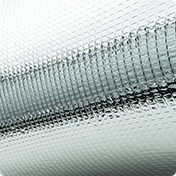

Embossed Double Aluminized Kapton® Film

Since 1985 Dunmore Aerospace has been providing material solutions for the space industry. Our embossed double aluminized Kapton® film is constructed of a polyimide film with a thin layer of aluminum deposited on both sides. This material is primarily used in the inner layers of an MLI blanket for high temperature spacecraft applications. The embossed pattern minimizes physical contact between layers in an MLI blanket. This chokes the conduction path, reducing the overall heat transfer between layers.

Reason to Choose Embossed Double Aluminized Kapton® Film

Embossed double aluminized Kapton® film is rated for a low to high temperature range. With both sides aluminized, most of the incident heat radiated to either surface is reflected. Embossed double aluminized polyimide film has similar applications to non-embossed double aluminized Kapton® film. The main advantage is the low contact area of embossed film eliminates the need to use Dacron mesh between layers since the embossing already reduces contact area. Eliminating the separating mesh reduces assembly complexity, potential debris issues, and results in a lighter weight MLI blanket for space critical applications.

Embossed double aluminized Kapton® film is an excellent choice for:

- Inner layers of an MLI blanket for low to high temperature applications

- Reducing overall weight of MLI blankets

- Low absorptance and emissivity applications

Material Properties

- Typical α / ϵ value: 3.5

- Operating temperature: -250°C to 290°C

- Thickness Range: 7.6 μm - 12.5 μm

- Surface resistivity: ≤ 1.0 Ω/sq

Embossed Double Aluminized Polyimide Film Application

Satellite MLI

DuPont™ and Kapton® are trademarks or registered trademarks of E.I. du Pont de Nemours and Company.