Double Aluminized Kapton® Film

Since 1985 Dunmore Aerospace has been providing material solutions for the space industry. Our Double aluminized Kapton® film is constructed of polyimide film with a thin layer of aluminum deposited on either side. Also known as DAK, the aluminum coating creates a first surface mirror, which provides exceptionally low absorptance and infrared emissivity values. It is most commonly used as the inner material for MLI blankets and to construct sunshields.

Reason to Choose Double Aluminized Kapton® Film

DuPont™ Kapton® film is a low to high temperature range material. By aluminum coating both sides, most of the incident heat radiated to either surface is reflected. A typical MLI blanket consists of 15 to 40 layers of double aluminized polyimide film separated from one another by a netting material. Since Kapton® film can withstand higher temperatures than polyester-based products and offers better UV protection, it may be used as the space-facing layer. Double aluminum polyimide film is also the preferred choice for the structure facing side of an MLI blanket due to its flame retardent properties.

Double Aluminized Kapton® film is an excellent choice for:

- Space side, inner layer, and structure side of MLI blankets

- Low to high temperature applications

- Excellent radiation resistance

Material Properties

- Typical α / ϵ value: 3.5

- Operating temperature: -250°C to 290°C

- Thickness Range: 7.6 μm - 127 μm

- Surface resistivity: ≤ 1.0 Ω/sq

Double Aluminized Polyimide Film Applications

Satellite MLI

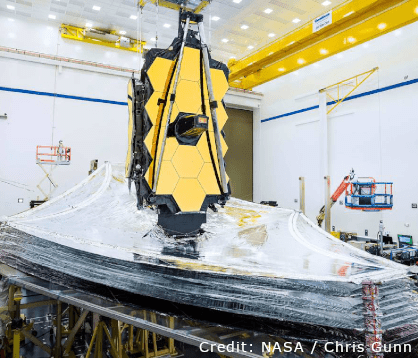

Sunshield

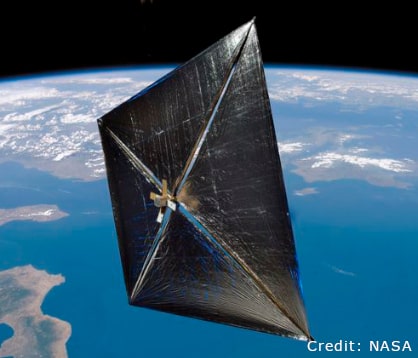

Solar Sail

DuPont™ and Kapton® are trademarks or registered trademarks of E.I. du Pont de Nemours and Company.