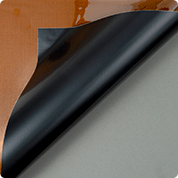

Black Kapton® Aramid Fabric Laminate

Since 1985 Dunmore Aerospace has been providing material solutions for the space industry. Our black Kapton® fabric laminate consists of black Kapton ® film laminated to Kevlar® fabric on one side and raw Kapton® film laminated to the other side. The utilization of Kevlar® fabric in the tri-laminate provides you with lightweight strength, durability, and impact resistance characteristics for your MLI blanket design. The black Kapton® laminate offers high emittance and absorptance as well as good electrical conductivity.

Reasons to Choose Black Kapton® Laminate

Our black Kapton® aramid fabric laminate is commonly used as a stopper layer in conjunction with a disrupter layer in MMOD applications. The disrupter layer (often beta cloth or Nextel® fabrics) braces the initial impact, breaking high-speed particles and dissipating the released heat. The stopper layer slows or stops the lower-velocity fragments that pass through the disruptor ensuring the safety of your spacecraft. In addition to its impact-resistant properties, the black Kapton® laminate offers high solar absorptance and emittance values, charge dissipation properties, and operates under a robust temperature range. The outer film layers also work to encapsulate the Kevlar® fabric, which is prone to fraying.

Black Kapton® laminate is an excellent choice for:

- MMOD stopper layer material

- Applications requiring high solar absorptance and emittance

- Charge dissipation

Material Properties

- Outside surface α / ϵ value: 1.10

- Operating Temperature: -200°C to 204°C

- Thickness: 175.3 μm

- Surface Resistivity: 105 to 107 Ω/ sq

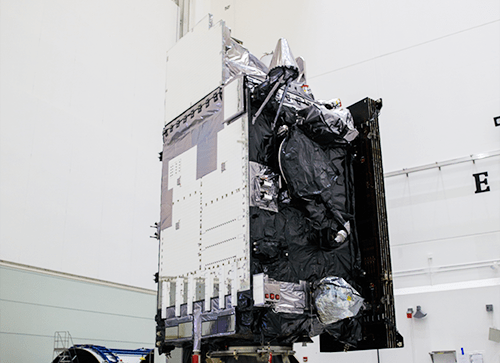

Black Kapton® Laminate Application

Satellite MLI

DuPont™, Kapton® and Kevlar® are trademarks or registered trademarks of affiliates of DuPont de Nemours, Inc.