Aluminized Kapton® Fabric Laminate

Since 1985 Dunmore Aerospace has been providing materials solutions for the space industry. Our aluminized Kapton® aramid fabric laminate is a tri-laminate structure consisting of aluminized Kapton® film laminated to both sides of Kevlar® fabric. The material provides MMOD protection and low solar absorptance and emittance values for your MLI blanket design.

Reasons to Choose Aluminized Kapton® Aramid Fabric Laminate

Our aluminized Kapton® fabric laminate is suitable for use as a stopper layer or the space facing side of an MLI blanket for MMOD applications. Stopper layers work in conjunction with a disrupter layer, which absorbs the initial impact and breaks apart the particles. The fragments then pass through a spacer and are stopped or slowed by the stopper layer, protecting the spacecraft underneath. The aluminized Kapton® fabric laminate is effective at absorbing the remaining momentum carried by these fragments, making it an ideal choice for stopper material. With aluminized Kapton® film on both sides, the material provides wide-temperature-range thermal insulation characteristics in addition to impact resistance. The aluminized Kapton® film also works to encapsulate the Kevlar fabric, which may fray otherwise.

Aluminized Kapton® fabric laminate is an excellent choice for:

- MMOD protection

- Applications requiring low solar absorptance and emittance

- Moderately low to high temperature applications

Material Properties

- Typical α / ϵ value: 3.5

- Operating temperature: -200°C to 204°C

- Thickness: 101.6 μm

- Surface Resistivity: ≤ 1.0 Ω/sq

Aluminized Kapton® Fabric Laminate Applications

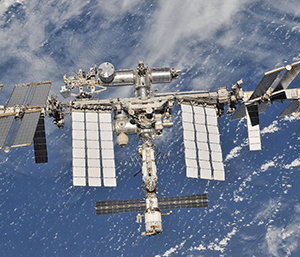

Space Stations, Credit: NASA

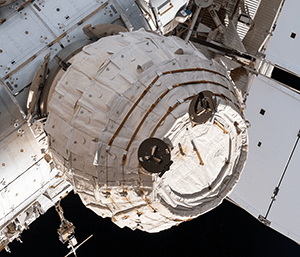

Inflatable Space Habitats, Credit: NASA

Satelllite MLI, Credit: NASA

DuPont™,Kapton®, Kevlar®, and Nomex® are trademarks or registered trademarks of E.I. du Pont de Nemours and Company.