Embossed Double Aluminized Polyester Film

Since 1985 Dunmore Aerospace has been providing material solutions for the space industry. Embossed double aluminized polyester film is constructed of a Polyethylene Terephthalate (PET) substrate with a thin layer of aluminum deposited on both sides. It is most typically used in spacecraft multi-layer insulation (MLI). Each layer is designed with an embossed pattern to minimize physical contact between layers. This chokes the conduction path, reducing the overall heat transfer between layers.

Reasons to Choose Embossed Double Aluminized Polyester Film

Embossed double aluminized polyester film is rated for a low to medium temperature range. With both sides aluminized, most of the incident heat radiated to either surface is reflected. The embossed film helps alleviate electrical and thermal shorts between blanket layers since the raised profile allows the layers to touch in fewer places versus a blanket utilizing flat double aluminized polyester film. Traditionally spacer material or netting is placed between MLI layers; however the process is time consuming and presents a particle contamination issue due to frayed fabric edges that is eliminated when using embossed materials.

Embossed Double Aluminized Polyester Film is excellent for:

- Inner-layer thermal insulation for spacecraft

- Low to mid-range temperature environments

- Cryogenic applications

Material Properties

- Typical α / ϵ value: 3.5

- Operating temperature: -251°C to 121°C

- Thickness range: 6.4 μm

- Surface resistivity: ≤ 1.0 Ω/sq

Embossed Double Aluminized Polyester Film Applications

Satellite MLI

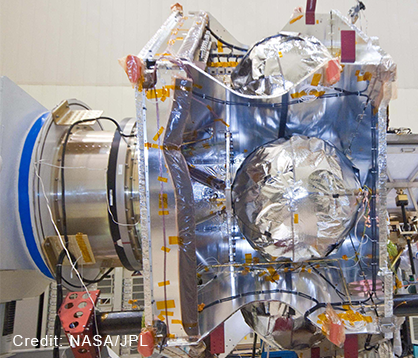

Satellite Propellant Tank

Vacuum Test Chamber