Double Aluminized Polyester Film

Since 1985 Dunmore Aerospace has been providing material solutions for the space industry. Our double aluminized polyester film is constructed of a Polyethylene Terephthalate (PET) film with a thin layer of aluminum deposited on both sides. Double aluminized PET film is also referred to as double aluminized Mylar® film. The material has a long and proven spaceflight heritage. It is most commonly used as inner material in satellite MLI blankets and for cryogenic applications.

Reasons to Choose Double Aluminized Polyester Film

Double coated aluminized polyester film is rated for a low to medium temperature range. With both sides aluminized, most of the incident heat radiated to either surface is reflected. MLI blankets are typically constructed of several layers of double aluminized polyester sandwiched between netting to mitigate heat transfer between a spacecraft and its surroundings. Double aluminized polyester film is not recommended for the space-side blanket layer since it does not offer sufficient UV protection.

Double alumimized polyester film is also widely used to protect aerospace cryogenic systems against external temperatures. Without proper insulation, cryopropellents (such as liquid oxygen or liquid hydrogen) can boil off, which is wasteful at best and could result in failures due to over-pressurization. Metalized polyester insulation film reduces heat leaks and maintains cryogenic fluid temperatures.

Double Aluminized polyester film is excellent for:

- Inner-layer thermal insulation for spacecraft

- Low to mid-range temperature environments

- Cryogenic applications

Material Properties

- Typical α / ϵ value: 3.5

- Operating temperature: -251°C to 121°C

- Thickness range: 6.4 μm - 127 μm

- Surface resistivity: ≤ 1.0 Ω/sq

Double Aluminized Polyester Film Applications

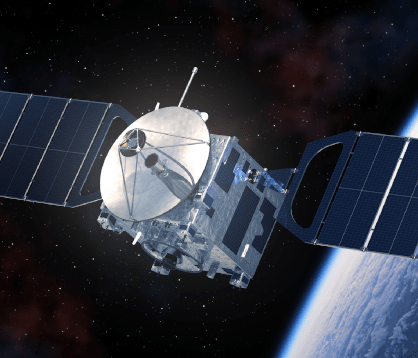

Satellite MLI

Satellite Propellant Tank

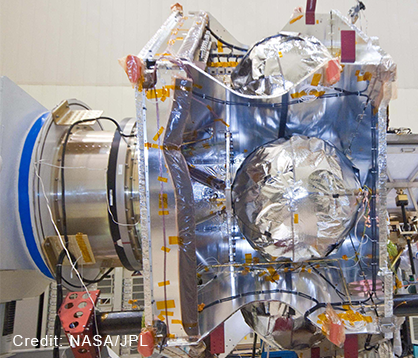

Vacuum Test Chamber