Aluminized Black Kapton® Film

Since 1985 Dunmore Aerospace has been providing material solutions for the space industry. Aluminized black Kapton® film is constructed of a carbon-filled polyimide film substrate with a thin layer of deposited aluminum on one side. It is most commonly used as outer layer material in MLI blankets. Aluminized black Kapton® film is used for low to high temperature applications that require high absorptance and emissivity properties.

Reasons to Choose Aluminum Coated Black Kapton® Film

While polyimide on its own is electrically insulative, the continuous strands of carbon in black Kapton® film dissipate charged particles. The aluminum coated side helps provide a continuous ground to the spacecraft. This material is a great choice for charged orbital environments, such as geosynchronous and low-earth orbits, where stray surface charges could harm ESD-sensitive components. The black side of aluminum coated black polyimide film also provides high absorptivity that is ideal for mitigating stray light when insulating optical instruments.

Aluminum coated black Kapton® film is an excellent choice for:

- Outer layer of MLI blankets

- Stray charge dissipation

- Stray light mitigation

- Low to high temperature range applications

Material Properties

- Typical outside surface α / ϵ values: 1.1

- Operating Temperature: -250°C to 290°C

- Thickness: 25 μm

- Surface Resistivity: 105 to 10 7 Ω/sq

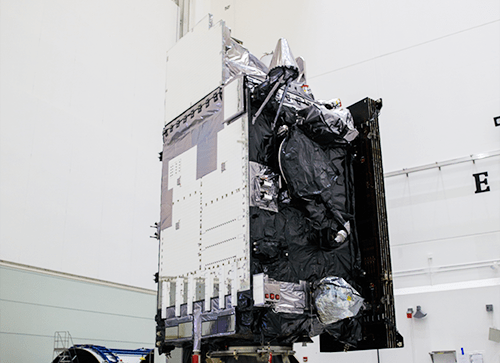

Alumininzed Black Kapton® Film Application

Satellite MLI, Credit: NASA/Kim Shiflett

DuPont™ and Kapton® are trademarks or registered trademarks of E.I. du Pont de Nemours and Company.

Contact Us for Aluminum Coated Black Polyimide Film

Please Contact Us for more information on aluminum coated black polyimide film.