Perforated Double Aluminized Polyester Film

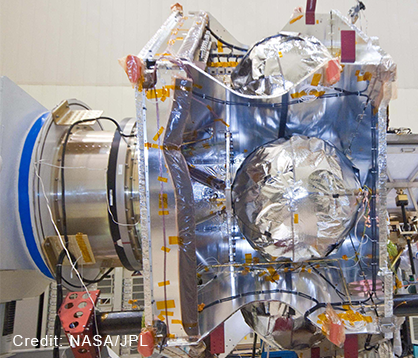

Since 1985 Dunmore Aerospace has been providing material solutions for the space industry. Perforated double aluminized polyester film is constructed of a Polyethylene Terephthalate (PET) substrate with a thin layer of aluminum deposited on both sides. It is commonly used in spacecraft multi-layer insulation (MLI) blanket applications. By perforating these layers, the MLI blankets are able to vent trapped air during the rapid depressurization of the ascent stage, allowing them to retain their form and avoid damage from swelling or tearing. Dunmore offers 30 standard perforation patterns and capabilities to accommodate custom designs.

Reasons to Choose Perforated Double Aluminized Polyester Film

Perforated double aluminized polyester film is rated for a low to medium temperature range and has a long spaceflight heritage. With both sides aluminized, most of the incident heat radiated to either surface is reflected. MLI blankets are typically constructed of several layers of perforated double aluminized polyester sandwiched between netting to mitigate radiative heat transfer between a spacecraft and its surroundings. This is the ideal material to mitigate the risk of trapped air in the MLI blanket when your spacecraft is entering the vacuum of space.

Perforated double aluminized polyester film is excellent for:

- Inner-layer thermal insulation for spacecraft

- Low to mid-range temperature environments

- Rapid pressure change applications

Material Properties

- Typical α / ϵ value: 3.5

- Operating temperature: -251°C to 121°C

- Thickness range: 6.4 μm - 23.4 μm

- Surface resistivity: ≤ 1.0 Ω/sq

Perforated Double Aluminized Polyester Film Applications

Satellite MLI