ITO Coated Aluminized Kapton® Film

Dunmore is a leading manufacturer of thermal control materials for the aerospace industry. Our ITO coated aluminized Kapton® film is constructed of an ITO coating on the first surface and an aluminum coating on the inside surface of polyimide film. The thermal management material is used as the outer surface of MLI blanket applications for low to high temperature applications. ITO coated aluminized Kapton® has moderate absorptance and emissivity values along with dissipating surface charges to mitigate electrostatic discharge (ESD) events.

Reasons to Choose ITO Coated Aluminized Kapton® Film

ITO coated aluminized polyimide has optical properties that will result in a warmer sink temperature compared to silver Teflon™ film or white Kapton™ film products. The optical properties of ITO coated aluminized polyimide film make are attractive for applications that do not have high solar heat fluxes. Examples of low heat fluxes are shaded sides of the spacecraft, highly elliptical orbits with long eclipses, or deep space missions. ITO coated Kapton™ film is an excellent option for missions that require a wide operating temperature range.

ITO coated aluminized Kapton™ film is a great choice for:

- Space side MLI

- Moderate α / ϵ applications

- Moderately low to high temperature applications

- Mitigating electrostatic build-up

Material Properties

- Typical outside surface α / ϵ value: 0.66 to 0.70

- Operating temperature: -185°C to 150°C

- Thickness range: 25 μm - 127 μm

- Surface resistivity: ≤ 2,500 Ω/sq

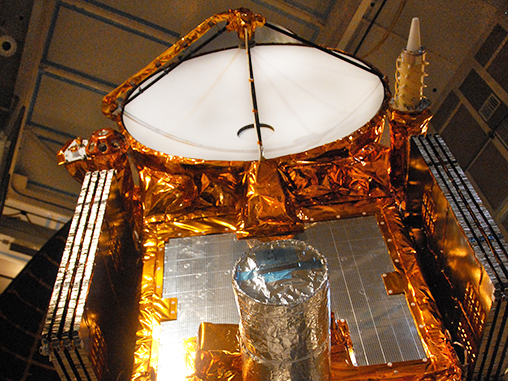

ITO Coated Aluminized Polyimide Film Application

Satellite MLI, Credit:NASA

DuPont™ and Kapton® are trademarks or registered trademarks of E.I. du Pont de Nemours and Company.